- For decades, an engine concept known as aerospike has been an elusive rival to the traditional bell-nozzle rocket.

- Although capable of delivering higher payloads while decreasing overall rocket weight, aerospike engines have never been seriously tested on the launchpad.

- The Germany military is putting some investment behind the idea as it awards a concept to a start-up busy designing a next-generation spaceplane.

Whether the German V-2 rocket, NASA’s legendary Saturn V, or SpaceX’s Falcon Heavy, all rocket engines share a common attribute: their exhaust nozzles are shaped like bells. The geometry of this nozzle is crucial because without it, rockets couldn’t produce enough thrust to get off launchpads, let alone escape Earth’s gravity.

But the old way of doing things isn’t always the best way.

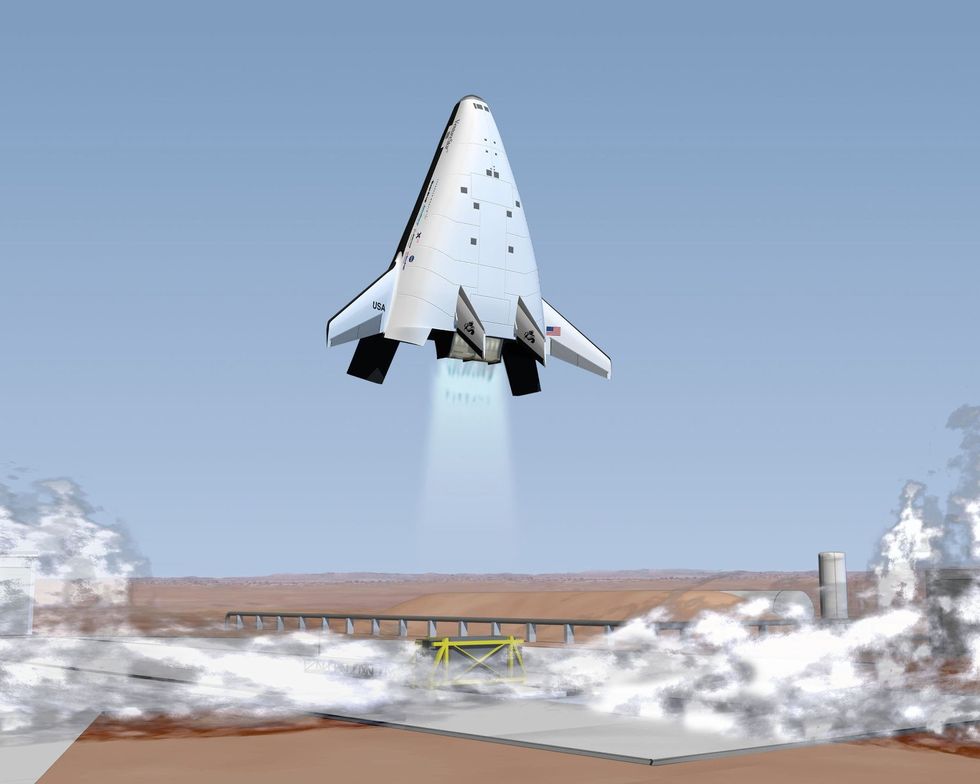

Since at least the 1950s, rocket engineers have wondered whether another nozzle design, known as the aerospike, could be a more efficient way to send humans to the stars. Although the concept has never propelled a real-world rocket (though NASA flew a demonstrator on the back of an SR-71 in the 1990s), the idea of the aerospike has remained remarkably resilient. Nearly 70 years after its initial inception, many, many, many aerospace startups have toyed with the idea of resurrecting the aerospike in recent years. The latest of these companies is the startup Polaris, which was awarded a German military contract in April to investigate the potential of using a linear aerospike (LAS) rocket engine in a spaceplane demonstrator.

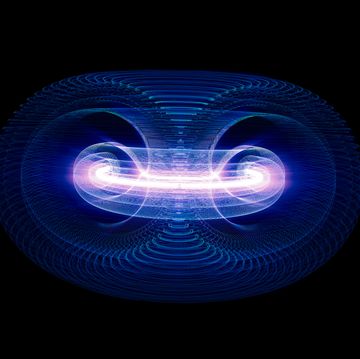

So, what exactly makes these engines so enticing, especially after the bell-nozzle has more than proved its worth throughout the history of human spaceflight? Rocket engines rely on air pressure to help lift payloads off the launchpad. At sea level, air pressure pushes on gasses exiting the rocket nozzle, and bell nozzles are essentially designed to work effectively at one particular altitude (the space shuttle rocket, for example, was more efficient in space than on the launchpad). However, if a rocket nozzle could somehow adjust to barometric pressure as it’s escaping the atmosphere, then it’d be capable of lifting higher payloads, reducing rocket mass (by being single-stage), and would just be an overall better engine. That’s the promise of an aerospike engine.

An aerospike engine relies on air pressure itself, rather than the walls of a bell, to control the exhaust exiting the rocket. This makes the engine capable of adapting to varying air pressures. Two types of aerospike engines—toroidal and linear—differ in shape (as their names suggest), but fundamentally work in the same way. NASA considered aerospike engines for the Space Shuttle before eventually opting for the conventional bell-nozzle. And Lockheed Martin designed the Space Shuttle successor—the X-33 spaceplane—with aerospike engines in mind, though the project was eventually scrapped.

Polaris’s LAS engine will fly in its spaceplane demonstrator, and will hopefully provide all the propulsion benefits of aerospike engines while also being a better fit for the flat-shaped spaceplane (i.e. avoiding tail strikes during takeoff and landing). In addition, the company believes it can overcome some of the engine’s design challenges—specifically, how to cool the thing—with recent advancements in 3D printing.

Only time will tell if Polaris finally puts the aerospike in space, or becomes just another failed attempt at revolutionizing human spaceflight.

Darren lives in Portland, has a cat, and writes/edits about sci-fi and how our world works. You can find his previous stuff at Gizmodo and Paste if you look hard enough.